Main technical parameters (QT8-15)

| Main technical parameters (QT8-15) | |

| Pallet size | 980*880mm |

| Max molding size | 930*830mm |

| Molding height | 50-200mm |

| Cycle time | 15-25sec |

| Vibration style | Movable and static table |

| Vibration force | 80KN |

| Total Power | ≈45KW |

| Gross weight | ≈9.5T |

Production table

| Production table | ||||

| The name of the brick | Brick sample | Brick specifications(MM) | Veneer production(piece) | Output (8 hours per shift) |

| Hollow block |  | 390*190*190 (400*200*200) | 8 | Approx. 13,440 pieces/189m³ |

| Solid block (Standard brick) |  | 240*53*115 | 45 | Approx. 86,400 pieces/126m³ |

| Pavement brick (Dutch brick) |  | 200*100*60 | 28 | Approx. 40,320 pieces/806m³ |

| Porous block (Small Eight Holes) |  | 240*115*90 | 21 | Approx. 35,280 pieces/88m³ |

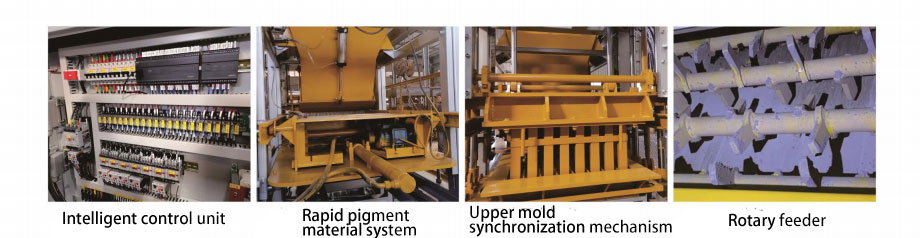

Feature

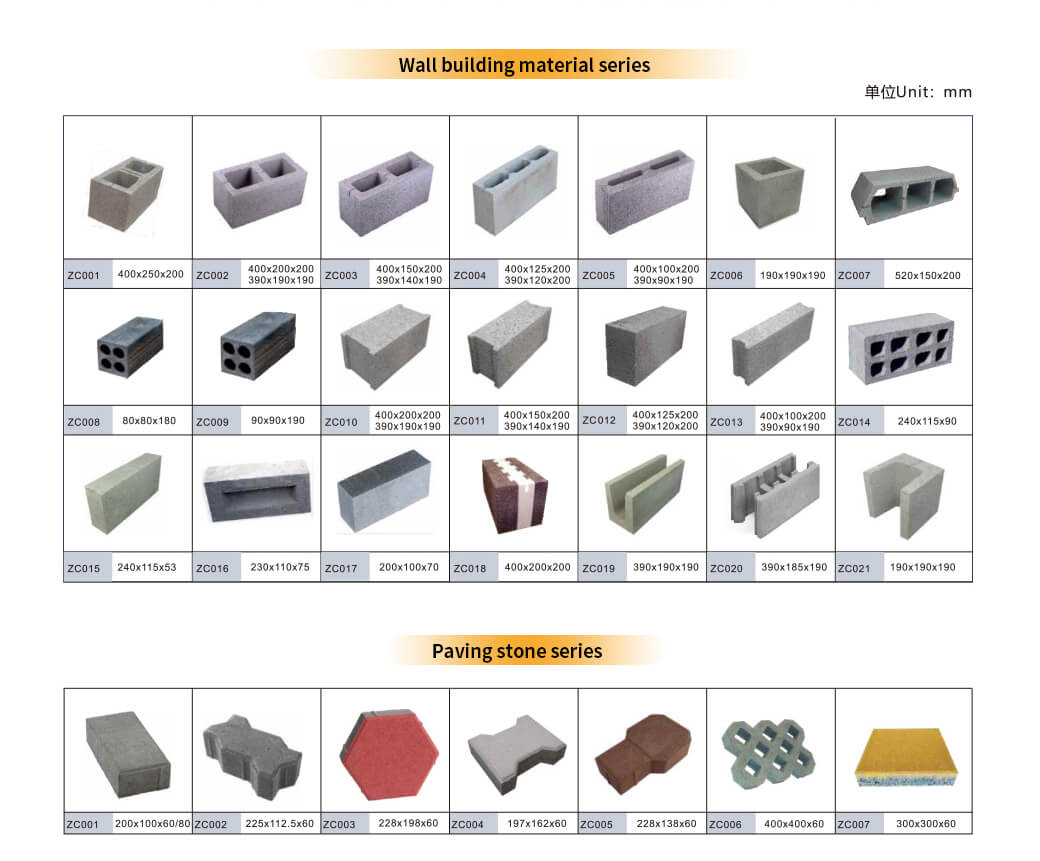

Block Patterns